Things do get a bit confusing since this subject is often debated.

The Controls and Instruments

Here are the engine controls in my plane: Carburator Heat, Throttle, Propeller Control, and Mixture.

Here is the standard C182 Instument cluster containing Cylinder Head Temperature (CHT), Oil Temperature, and Oil Pressure.

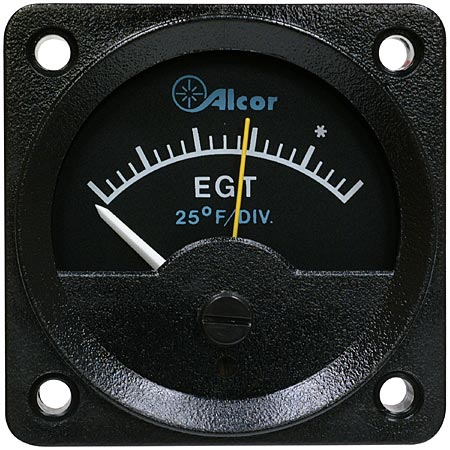

Here is a multipoint engine analyzer which shows EGT and CHT for each cylinder. This is very good since different cylinders will be slightly different temperatures during normal operation. That way all cylinders are checked to be appropriate mixtures. Also if a cylinder starts having problems, it will show up here as one cylinder having a larger EGT or CHT difference.

Here is a multipoint engine analyzer which shows EGT and CHT for each cylinder. This is very good since different cylinders will be slightly different temperatures during normal operation. That way all cylinders are checked to be appropriate mixtures. Also if a cylinder starts having problems, it will show up here as one cylinder having a larger EGT or CHT difference.

In my C182, I pull partial carb heat while cruising so that my carb temperature is 10 degrees C. This makes the EGT differences between cylinders smaller and the engine operates a little better. Fuel injected engines will have even tighter EGT differences due to very even fuel distribution and this is part of why they operate a little more efficiently. If you don't have the carb temperature gauge, do not use partial carb heat; only full carb heat on or off.

Why Lean?

Leaning can be important for a number of reasons. It can give you better power and speed at altitude. You need to lean in order to plan your fuel more accurately for long cross country trips; you don't want to run out of fuel, and the performance charts count on you leaning. If you own your own plane, it saves you gas and money.

Running Lean of Peak EGT is a hot point of debate, but it does not work very well in carburated engines like the older C182 so I will not talk about it much here.

How to lean is a choice you have to make. There is a lot to learn as well, and I am still learning/exploring. If you own the plane that is especially important. If you rent, you should probably use the owner/instructors recommendation.Web Articles

I have been looking over the web extensively and trying to find articles that both describe how to run the mixture and the physics behind it. The best articles I think I have found are John Deakin's old Avweb Pelican's Perch articles. They talk a lot about engine operation and base it on physics. Much of it sounds like it follows what is taught at Advanced Pilot Seminars for engine management. He talks a lot about Lean of Peak, but I am trying to grab the information just on Rich of Peak.John Deakin's articles:

- How to lean on the ground

- Where should I run my engine (Part 1)

- Where should I run my engine (Part 2) The Climb

- Where should I run my engine (Part 3) Cruise

- Where should I run my engine (Part 4) The Descent

- Mixture Magic

For pictures of what do do with a single point EGT, this Rod Machado article about leaning is pretty good.

Mike Bush's Savvy Aviator article list on Avweb is excellent for engine management and general airplane maintenance. There are a number of articles there; they basically follow the same principles as John Deakin's articles.There appears to be quite of maintenance information the Sacramento Sky Ranch knowledge base web site.

I will try to summarize what I have read. See the full web site descriptions for more details.

Leaning for Taxi

Most people follow the recommendation to lean aggressively while taxiing. The idle mixture is set for starting an engine which is much too rich for taxiing. Prolonged taxi with full rich mixture will foul the spark plugs over time.Mixture for Takeoff

Mixture should be full rich for all but high altitude takeoffs. Throttle should also be pushed full forward for most of the climb since that enables an extra richening feature in many carburators which is important for full power operation. Talk with an instructor for leaning at high altitude; you want to find the climb mixture, but on the ground before takeoff.Mixture for Climb

When climbing, maintain the EGT that appears at Sea level when full rich or something around 250-300 rich of peak or richer for all cylinders. Most non-turbocharged engines have a peak EGT around 1525-1550, so this will probably be around 1275. Those are some typical numbers; you have to determine them for your engine and EGT probe location.Leaning for Rich of Peak Operation

During cruise, the EGT setting is found as follows. Lean the mixture 1/2 turn counter clockwise, wait 3-5 seconds, and watch the EGT gauge. It will start going higher. Repeat until you see it go lower. The top temperature is the peak EGT. If you want to be 100 degrees Rich of Peak (ROP), then you want to enrichen the mixture back to the peak, then 1/2 turn clock wise rich, wait and repeat, until the temperature reduces by 100 degrees from the peak temperature.If you have single point EGT, the above is close to what you want to do. It will only be checking one cylinder, but hopefully the probe is on the leanest cylinder by design. If that is the case, all cylinders will be 100 ROP or richer.

You might want different amounts of ROP depending on the percentage horsepower that your power setting is currently at. A particular Manifold Pressure and RPM setting will yield a particular horsepower that is specified in the POH. Be careful that your RPM gauge is displaying the correct RPM; many are out of adjustment and indicate lower than real. Check it with an optical RPM gauge. If it is wrong, you could be developing more HP than you think and be at the wrong ROP setting.

If you have a multipoint engine analyzer such as one by JPI or Electronic Instuments, there are usually automated ways to do this procedure. You want to do it so that all cylinders are the desired ROP setting or richer.Lean of Peak (LOP) would be done similar, but all cylinders would be leaner than the peak and the richest cylinder would be leaner than the LOP setting. This is difficult in my carburated C182 engine due to uneven fuel/air distribution from the carburated system, and it is a very debated topic so I will not discuss it now.

The Red BoxMany places either talk directly about a red box or at least the need of not operating too lean while operating at high power settings or not being too lean when Rich of Peak. John Deakin refers to this Red Box description in his Pelican Perch article on Where Should I Run My Engine (Part 3-cruise):

- At high power at Sea Level, operate full rich and full throttle for extra enrichening. This should place you at 250-300 Rich of Peak (ROP). Anything leaner is bad.

- At about 80% horsepower, 200ºF ROP to 60ºF LOP is bad.

- At about 75% horsepower 180ºF ROP to 40ºF LOP is bad.

- At about 70% horsepower 125ºF ROP to 25ºF LOP is bad.

- At about 65% horsepower or so, 100ºF ROP to Peak is bad.

- At and below about 60% horsepower, there is no red box. Put the mixture wherever you want it.

As the red box is described by John Deakin, it also means that 60% horsepower is a good place to be since any mixture is good. I have heard it is still best to make sure you preferrably don't end up with some cylinders LOP and some ROP. Aim for all cylinders to be all ROP or all LOP.

These cruise mixture settings will end up with richer EGT settings than what is specified in most POHs unless you are 60% hp or lower where any mixture is ok. If you believe John Deakin, Mike Bush, and Advanced Pilot Seminars, this is the way to go. I think it is the way I will aim to put my mixture. If your mixture is richer than the POH specified setting, realize you will burn fuel at a higher GPH rate.

Cylinder Head Temperature (CHT)

Through all these different mixtures, you should try to maintain a CHT lower than what the factory indicates. This will lengthen how long the engine will last and is easily attainable if the baffling and seals around the engine are in decent shape and control the air flow past the cylinder cooling fins appropriately. I try to keep my CHT under 390 degrees and preferrably much cooler. But John Deakin also advises in Pelican Perch to not adjust mixture for this top CHT temperature; adjust mixture with the red box in mind and then make sure it stays below a CHT threshold.

Burned Exhaust Valves

I am searching for articles on burnt exhaust valves as well and have found these interesting articles:

- Pelican Perch: Burnt valves not related to LOP operation

- Sacramento sky ranch: Mixture and burnt valves

- Sacramento sky ranch: Stuck valves

Once again, it is your choice on how to operate your plane. I am still exploring and learning. Talk with your mechanic, instructor, and others and form your own opinion. There are lots of opinions on this, and they seem to be in flux these days.

Any comments on my interpretations that do not involve Lean of Peak?

/Brian

7 comments:

Excellent post, but be a tad careful with many hangar flying opinions about engine management. Leaning procedures are fairly standardized in normally aspirated engines, but in supercharged or turbocharged engines that is not always true.

In terms of lean-of-peak, this may be the academically better concept, but most normally aspirated engines don't run smooth lean-of-peak, hence the typical manufacturer's recommendation is to run rich-of-peak for those engines.

I believe the "red box" you refer to is basically the idea that operating exactly at, or very close to, best power mixture (peak EGT) is always detrimental to the engine.

Good points. These are my thoughts on operating the Cessna 182P normally aspirated (non-turbocharged) Continental O470R. Please read up and talk to people to form your own opinions for your engine management.

/Brian

I think pretty high on my list is to take the Advanced Pilot Seminar on Engine Management in order to better under stand the nuances of engine management and feel best about the methods I use.

/Brian

wow..this is very nice blog..

i realize something on this..

thank you so much for sharing..

Interesting learning. Helpful for anyone interesting on aviation.

everything just sounds wonderful, but i am a hillbilly and not very smart, even though i fly a and own a 182. this is very complicated for me, and i wish there was something more simple. all i have is a egt, and cylinder head temp. the same ones that came with the airplane when it was new. don

This was a loveely blog post

Post a Comment